The Journey of Exceptional Rwandan Coffee

Every cup of MIG LTD coffee tells a story that begins in the verdant hills of southern Rwanda and unfolds through a meticulous process designed to preserve and enhance the unique qualities of our terroir. Follow this remarkable journey from seed to sip—a testament to our commitment to quality at every stage.

Cultivation: Nurturing Excellence

Our approach to cultivation balances traditional wisdom with modern sustainable techniques:

Shade-grown cultivation

under native trees that protect plants and enhance biodiversity

Organic fertilization methods

utilizing compost created from processing byproducts

Integrated pest management

reducing the need for chemical interventions

Precision pruning techniques

ensuring optimal plant health and cherry development

Water conservation systems

protecting this precious resource while ensuring plant vitality

Bourbon: Our Heritage Variety

While many coffee-growing regions have transitioned to higher-yielding varieties, we remain committed to Bourbon—Rwanda’s heritage coffee variety known for its exceptional cup quality. Though more challenging to grow, Bourbon produces cherries with higher sugar content and complex flavor profiles that define the distinctive character of Rwandan specialty coffee.

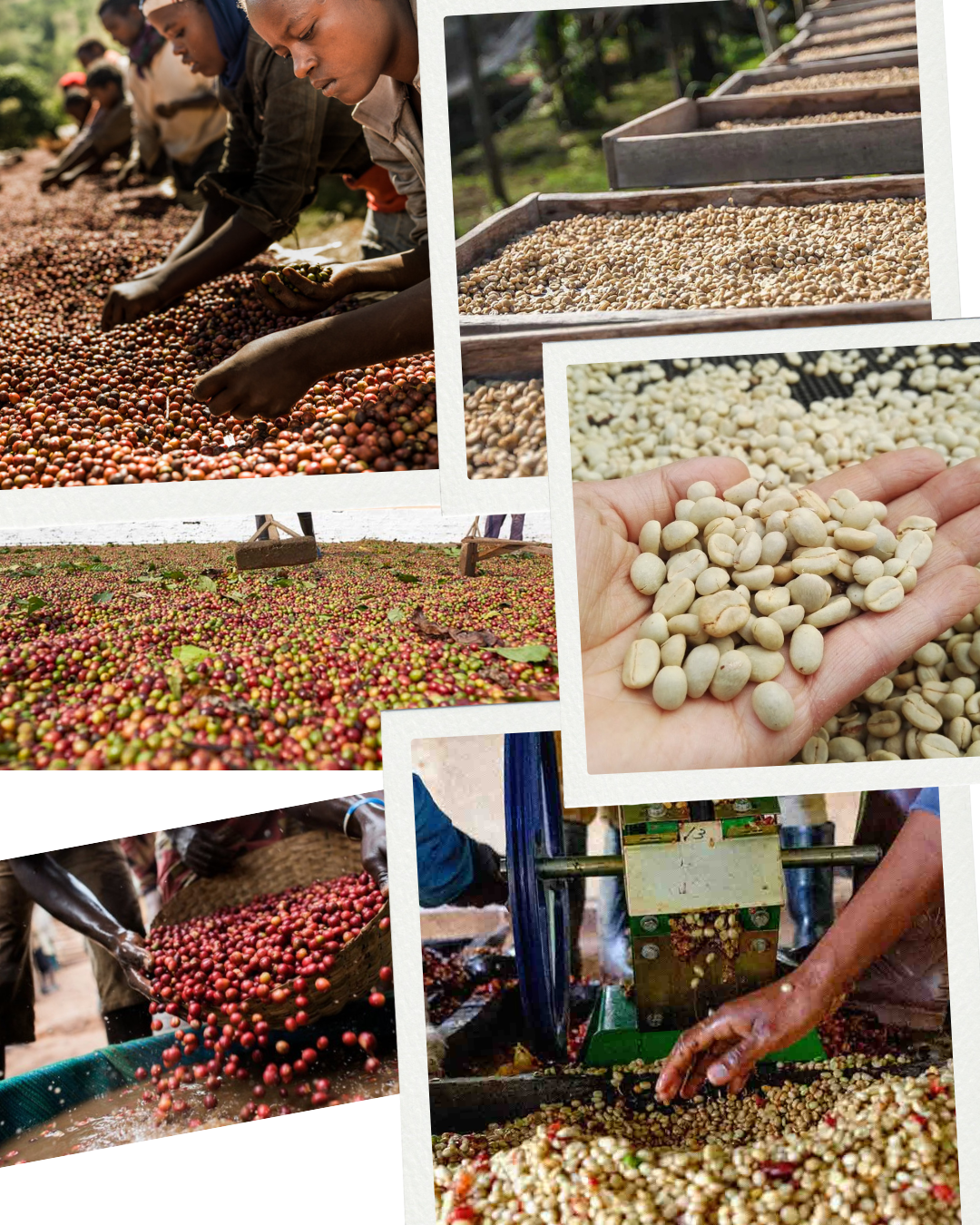

Harvest: The Art of Selection

Hand-Picking at Peak Ripeness

Unlike commercial operations that strip-pick entire branches, our harvesting is an exercise in patience and precision:

- Each cherry is individually hand-picked only when it reaches optimal ripeness

- Harvesters make 4-6 passes through the same areas over the harvest season

- Initial sorting occurs in the field, with unripe or overripe cherries separated

- Same-day delivery to washing stations ensures freshness is preserved

- Strict quality controls include flotation testing and visual inspection

This labor-intensive approach ensures that only the finest cherries—those at the perfect stage of ripeness—continue to the processing stage, setting the foundation for exceptional quality.

Processing: Precision and Care

Washing Stations: Centers of Excellence

Our four washing stations in Huye and Nyamagabe serve as quality control hubs where careful processing preserves and enhances the intrinsic qualities of our coffee:

The Washed Process

- Reception and Sorting

- Cherries are weighed and inspected for quality

- Float tanks separate lower-density cherries

- Final hand sorting removes any remaining defects

- Pulping

- Custom-calibrated machines gently remove the outer fruit

- Precision settings preserve the integrity of the bean

- Minimal water usage through recirculation systems

- Fermentation

- Natural enzymes break down remaining mucilage

- Controlled fermentation tanks maintain optimal conditions

- 12-18 hour process monitored hourly for perfect development

- Temperature and pH carefully tracked throughout

- Washing

- Clean mountain water removes fermentation residue

- Channel grading separates beans by density

- Multiple washing cycles ensure complete cleaning

- Drying

- Beans spread thinly on raised African beds

- 15-21 day drying period with constant turning

- Protected from direct sun during peak hours

- Covered at night to prevent moisture reabsorption

- Moisture content monitored until it reaches precisely 10.5-11%

Quality Control: Relentless Standards

Multiple Inspection Points

Our quality assurance doesn’t end with processing—it continues through multiple stages of rigorous evaluation:

Green Coffee Analysis

- Moisture and water activity testing

- Screen size sorting for uniformity

- Defect counting to ensure only top grades advance

- Density measurements predicting roasting behavior

Sample Roasting and Cupping

- Every lot evaluated through standardized protocols

- Flavor profiling against established quality benchmarks

- Minimum SCA cupping score of 85 for premium offerings

- Expert panel consensus required for approval

Pre-Export Selection

- Final hand sorting removing any remaining defects

- Vacuum packaging to preserve freshness during transport

- Traceability documentation linking to specific harvest lots

- Quality certificates verifying adherence to standa

Roasting: Revealing Potential

The Final Transformation

At our roasting facility in Kigali, we approach each coffee with a carefully calibrated roasting profile designed to highlight its unique characteristics:

- Small-batch approach ensuring attention to detail

- Origin-specific profiles developed through extensive testing

- Precision equipment monitoring temperature development curves

- Post-roast resting periods allowing flavors to stabilize

- Rigorous quality control ensuring consistency across batches

- Packaging within hours to preserve peak freshness